Building a new product is exciting but a difficult endeavour at the same time. No two products are same and that is why the initial idea, research and prototype of each product is different. In this competitive landscape of manufacturing and technology, the efficiency and accuracy of a product development becomes very crucial. This is where ATE (Automated test equipment) comes in to contribute a critical role in streamlining the overall product development process.

According to Grand view research, the global automated test equipment market size was valued at USD 7,643.8 million in 2023 and is expected to register a compound annual growth rate (CAGR) of 3.2% from 2024 to 2030. This is because the demand for connected devices and consumer electronics is at the all-time high and, increasing with an exponential pace driving many companies to increase the focus on quality improvement along with end-to-end testing solutions.

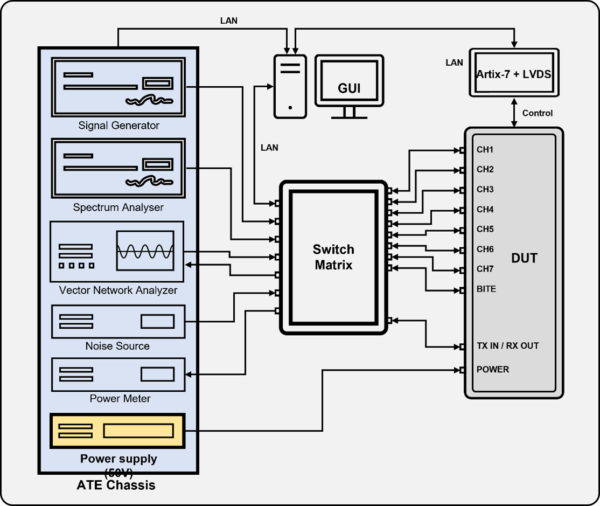

ATE, also referred to as automatic test equipment, is employed for testing the functionality, performance, certification, and safety requirements of electronic devices. It allows for the automation of testing for modules, systems, devices, and products, assisting in the monitoring and control of processes or devices, validating compliance standards, and identifying and minimizing related risks. ATE becomes useful for various industries like aerospace, automobile, retail, and many more for data acquisition and diagnostic.

ATE systems have transformed the way products are tested and confirmed. These automatic testing systems provide a variety of advantages that are essential for guaranteeing the quality and dependability of products in today’s world. Let us look:

Time to market is a significant factor that can make or break a company. As per an article published by Harvard business review “On average, companies lose 33% of after-tax profit when they ship products six months late, as compared with losses of 3.5% when they overspend 50% on product development”. This is where ATE can help companies to fasten up the roll out time as ATE significantly reduces the time required for testing by automating repetitive tasks and enabling simultaneous testing of multiple units. This increased speed allows for faster identification and resolution of issues, accelerating the overall product development cycle. ATE significantly reduces the time required for testing by automating repetitive tasks and enabling simultaneous testing of multiple units. This increased speed allows for faster identification and resolution of issues, accelerating the overall product development cycle.

Human error is a common challenge in manual testing processes that needs to be addressed properly for a high efficiency and reliable product. ATE minimizes these errors by providing consistent and repeatable test results, ensuring higher accuracy and reliability. This precision is critical in industries where even minor deviations can lead to significant problems like aviation. Healthcare, etc.

While the initial investment in ATE may be high, the opportunity for future cost reductions is considerable. Automated testing reduces labour costs, decreases the need for rework by catching defects early, and enhances product quality, leading to lower returns and warranty issues.

ATE systems have the capability to conduct a diverse array of testing, ranging from basic assessments to intricate analyses. Their ability to be used in multiple applications in industries such as electronics, automotive, aerospace, and telecommunications makes them versatile.

During the design phase, ATE is used to verify that prototypes meet design specifications. This early testing helps identify potential design flaws before mass production begins, saving time and resources.

ATE is integral in the manufacturing phase, where it ensures that products coming off the assembly line meet quality standards. Automated systems can perform high-speed tests on each unit, maintaining consistent quality across large production volumes.

After production, ATE can be used for final quality checks and troubleshooting. This ensures that only fully functional and reliable products are shipped to customers, enhancing brand reputation and customer satisfaction.

Before starting the process, we must define the key functions and features such as power consumption, voltage levels, digital logic, analogue signals, and communication interfaces.

Budget is important as setting up a realistic budget goes a long way in purchasing the initial equipment, potential upgrades, ongoing expense.

The implemented ATE must be reliable so that it can minimize disruptions to production schedules and reduce test costs.

ATE must be scalable so that you can avoid future equipment replacement or upgrades by proper anticipating the future test volume.

Protection of equipment and personnel during testing operations is important that is why ensuring that the ATE incorporates safety features is essential.

Good maintenance and support can help you bring the overall operation cost while making sure that the downtime is minimum. That is why doing preliminary research about the available service.

Various sectors such as healthcare and aerospace have regulations to follow. When selecting an automated testing device, ensure it complies with these standards and can offer the needed certifications.

ATE is crucial in guaranteeing the dependability and effectiveness of aerospace and defence systems. ATE helps with efficient and accurate testing of components and systems, assisting in quality control, validation, and meeting strict industry standards.

ATE plays a crucial role in guaranteeing the safety and efficiency of medical electronics. They allow thorough testing of medical devices and electronic sub-systems, ensuring adherence to regulatory standards and providing dependable healthcare solutions.

It can be utilized to evaluate the performance of different integrated circuits that operate modern vehicles, such as advanced driver-assistance systems (ADAS), infotainment systems, braking units, batteries, active alignment systems, and other parts.

ATE is utilized to evaluate the functionality of consumer electronics, including smartphones, tablets, radios, televisions, appliances, speakers, headphones, and fitness wearables.

Lastly, it is also used to test various equipment including set-top boxes, CPE, residential gateways, cable-modem termination systems, and optical transponders.

Comprehending the basics of Automated Test Equipment (ATE) is crucial in today’s intricate electronics industry as it plays a vital role in contemporary product creation, providing unparalleled speed, precision, and effectiveness. Through the incorporation of ATE in the development process, businesses can guarantee improved product quality, cost reduction, and faster time-to-market. With technology advancements, the importance of ATE will increase, making it a smart choice for forward-looking companies.